Multy-purpose Laboratory System

Technical data

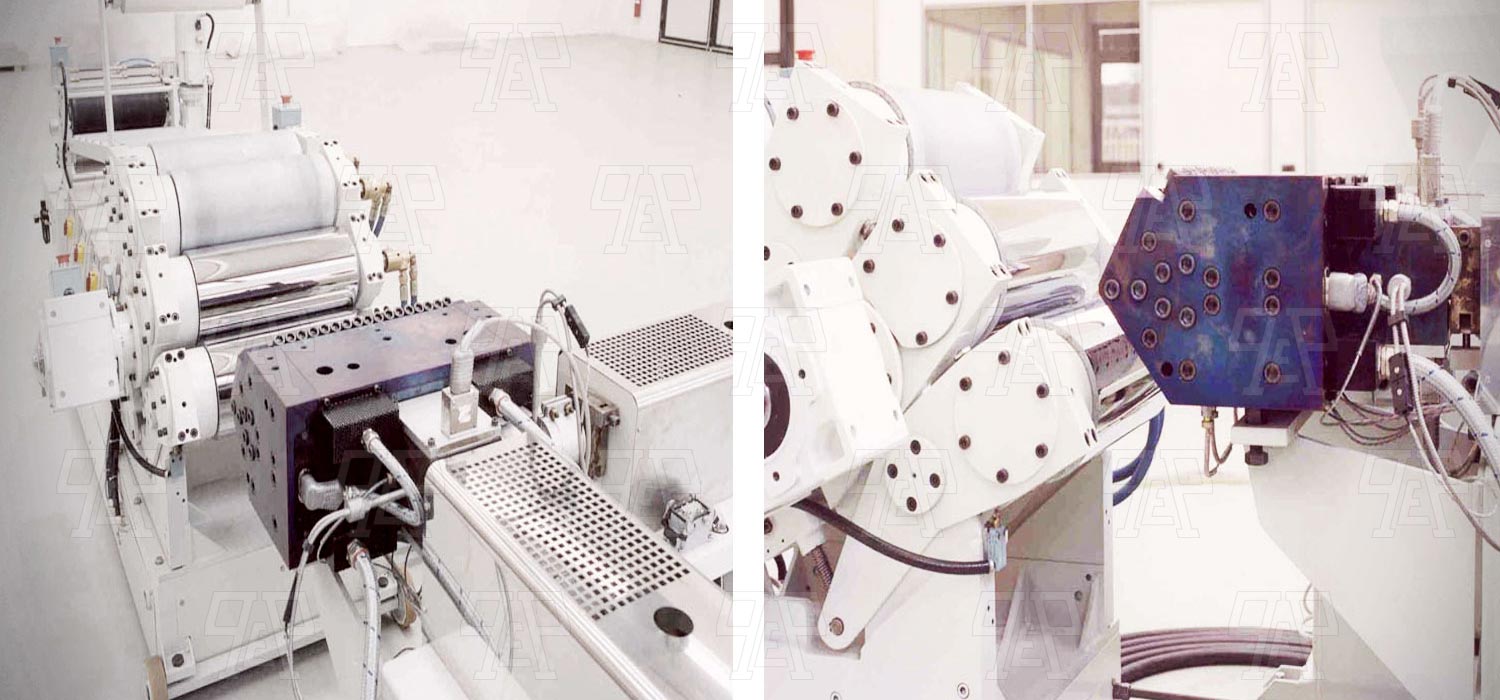

Extrusion:

- Two single-screw extruders, ø 30mm – L/D 30 with or without venting

- Motor 4 Kw, RPM 0-100, output 10 Kg/h

- Feeding materials: PP, PE, PS, ABS, PU, PET, PMMA, PC

Head:

- 3-layer type, 450 mm wide, thickness 0,25-2,5 mm

Calendering:

- With 4 rolls, ø 200 x 450 mm

- Mechanic closing up to 150 Kg/cm

- The calibration is feasible between: 1st-2nd roll; 2nd-3rd roll; 3rd-4th roll

- Transmission by motoreducer Kw 1,5 driven by inverter

- Indipendent thermoregulation of each roll by means of 4 water-pressurized units

Take-off unit:

- With 2 steel and rubbered rolls, ø 160 x 450 mm

- Motoreducer Kw 0,37 driven by inverter

Winder:

- With constant tensioning and pneumatic expander, ø 75 x 500 mm

- For bobbins having max ø 400 mm

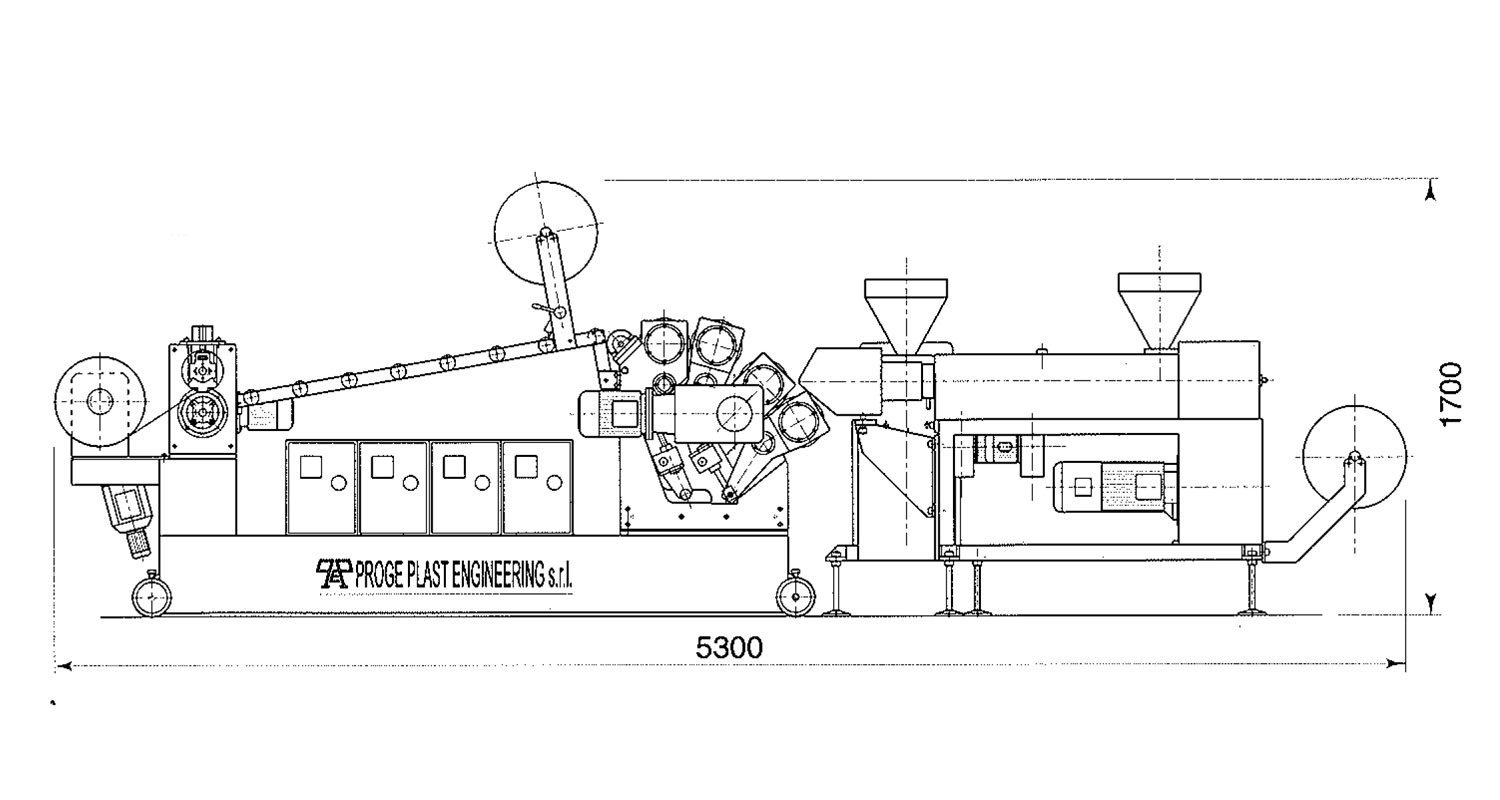

Version 1.

2/3 layers coextrusion, thickness from 0,1 up to 2,5 mm, with smooth or embossed surface

2/3 layers coextrusion, thickness from 0,1 up to 2,5 mm, with smooth or embossed surface

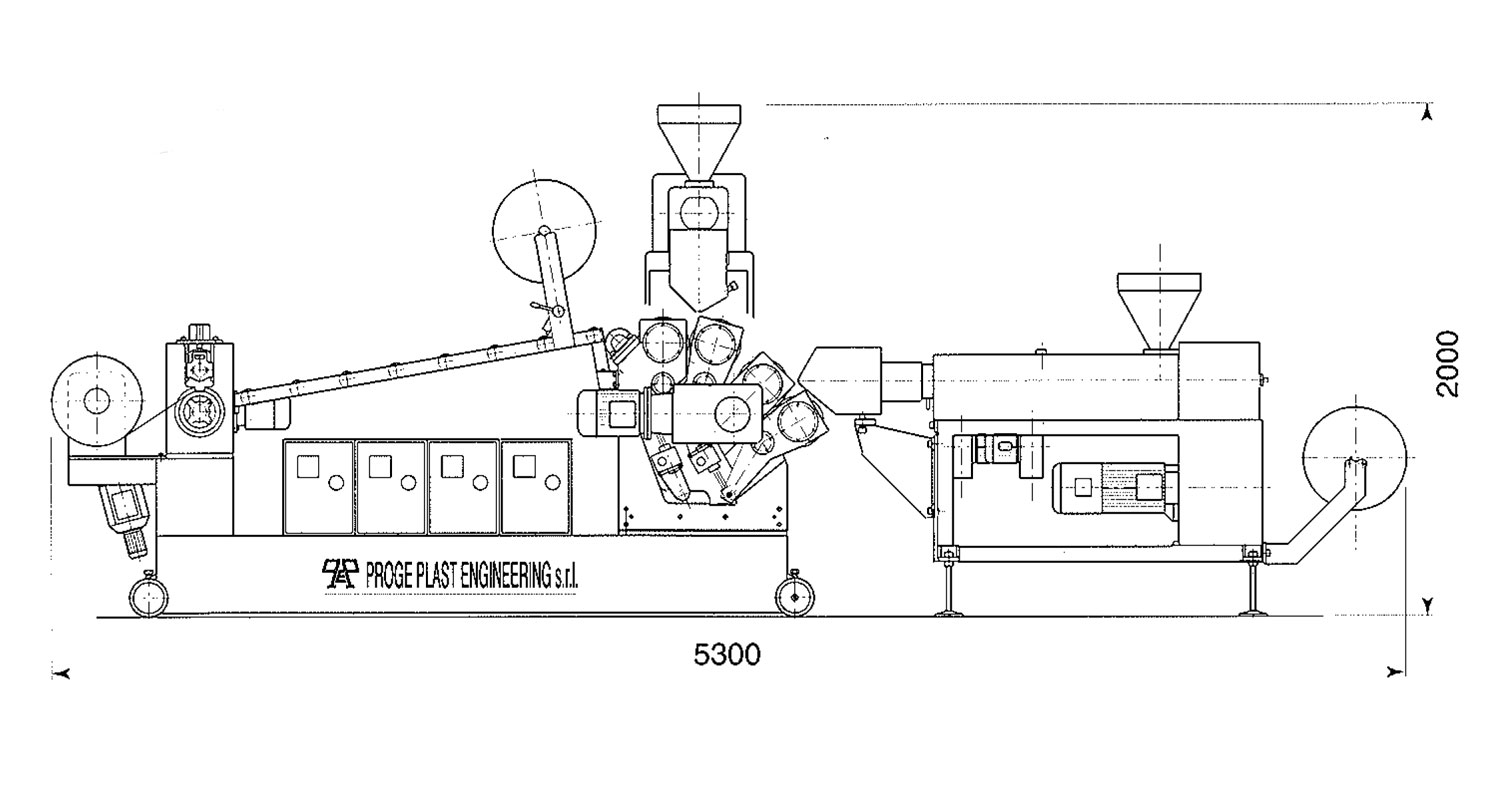

Version 2.

2 layers coextrusion (coating) with the option of adding some reinforcements between the 2 layers. One side extruder and 1 head 450 mm, thickness from 0,2 up to 2 mm, are located between the 3rd and the 4th roll of calendar

2 layers coextrusion (coating) with the option of adding some reinforcements between the 2 layers. One side extruder and 1 head 450 mm, thickness from 0,2 up to 2 mm, are located between the 3rd and the 4th roll of calendar

Proge Plast Engineering

Proge Plast Engineering

Proge Plast Engineering

NEED MORE INFO?

Want to learn more about how Proge Plast Engineering can help your business? Click below to get in touch.