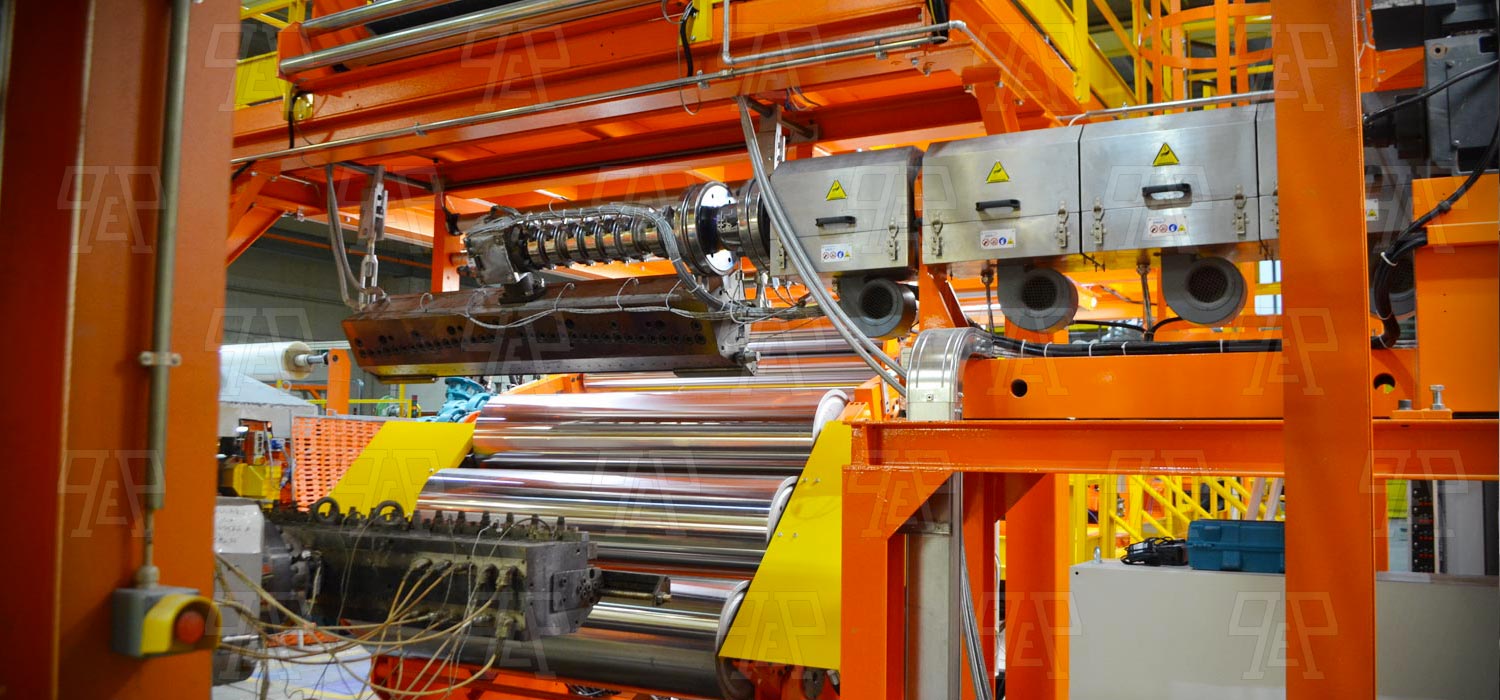

CALENDERS

Robust, adjustable, safe

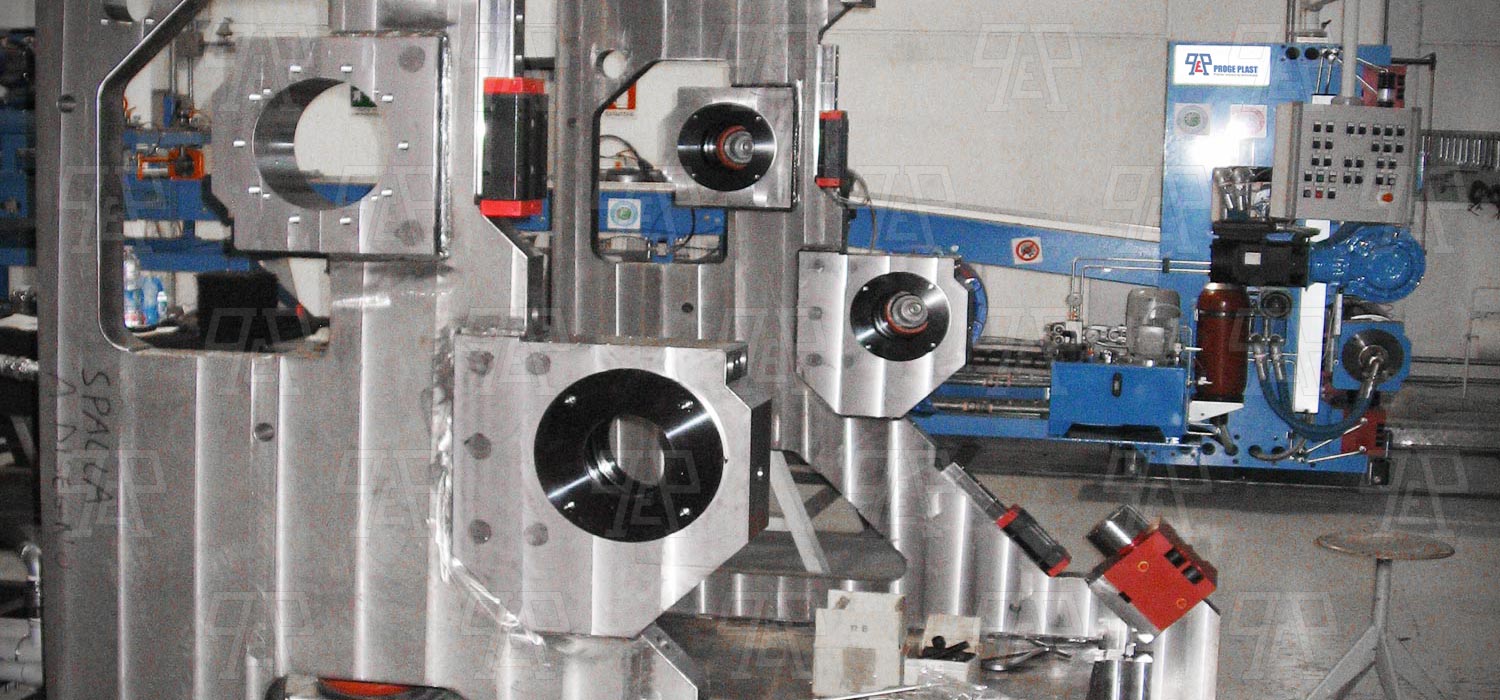

Two sturdy steel shoulders joined with a series of crosspieces to a base, create a compact and solid structure

Fixed cylinder (master) or mobile cylinders operated by hydraulic pistons positioned on sturdy caps which support the cylinders. Thickness adjustment pre-configured for operation via control panel, performed by a mechanical wedge system

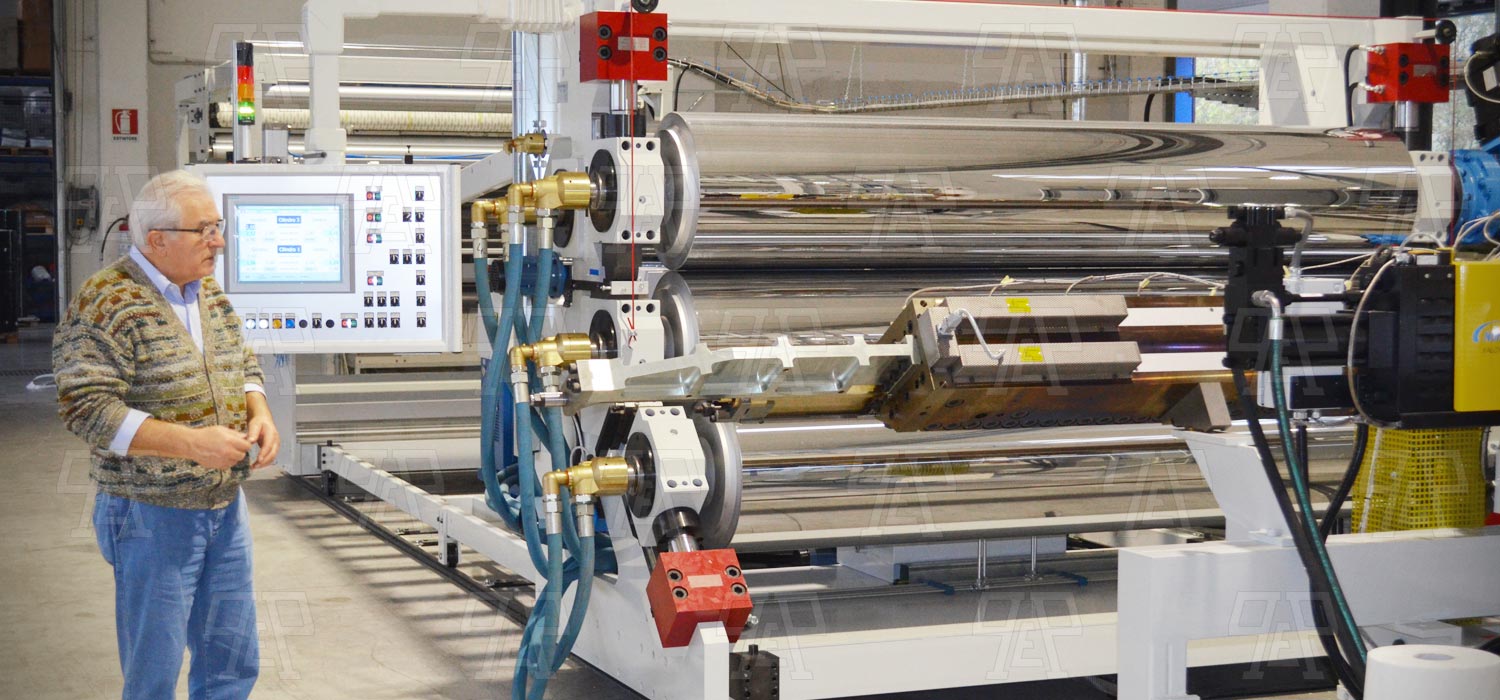

PLC calender control

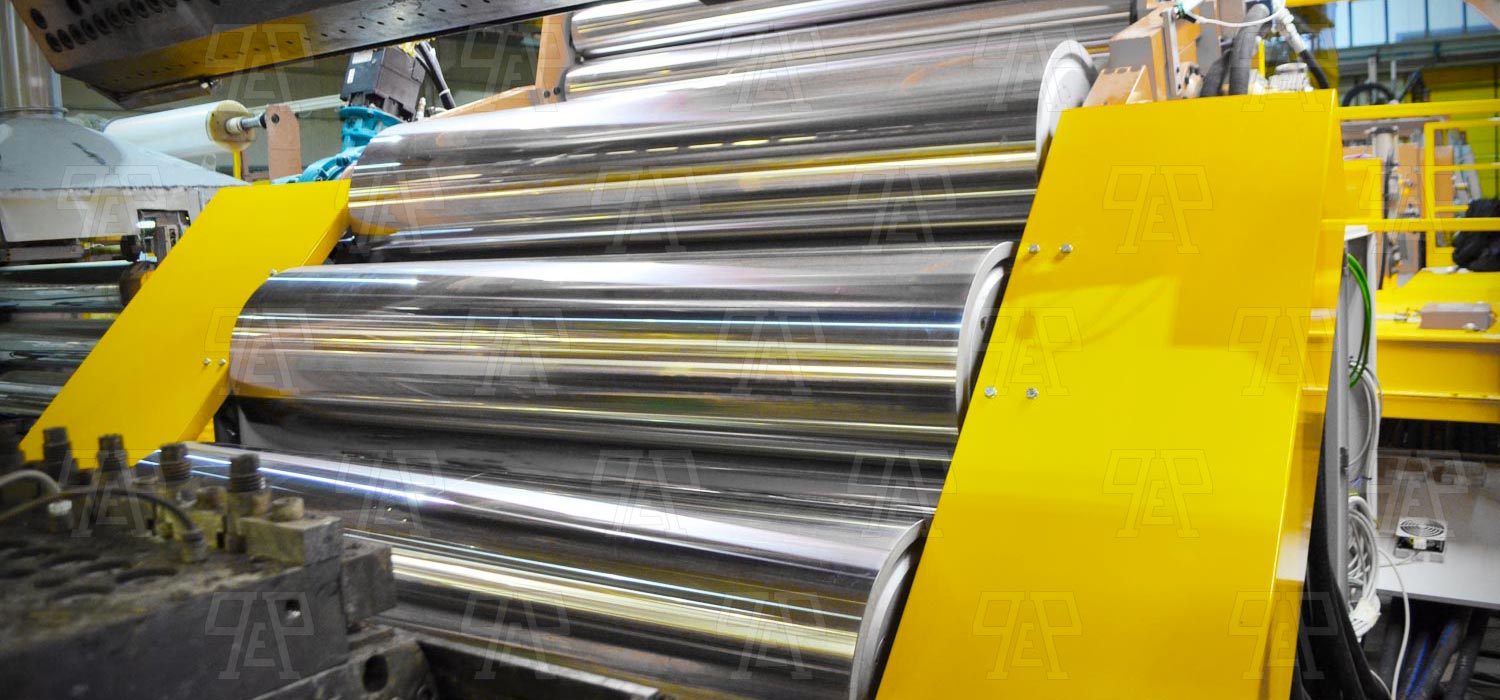

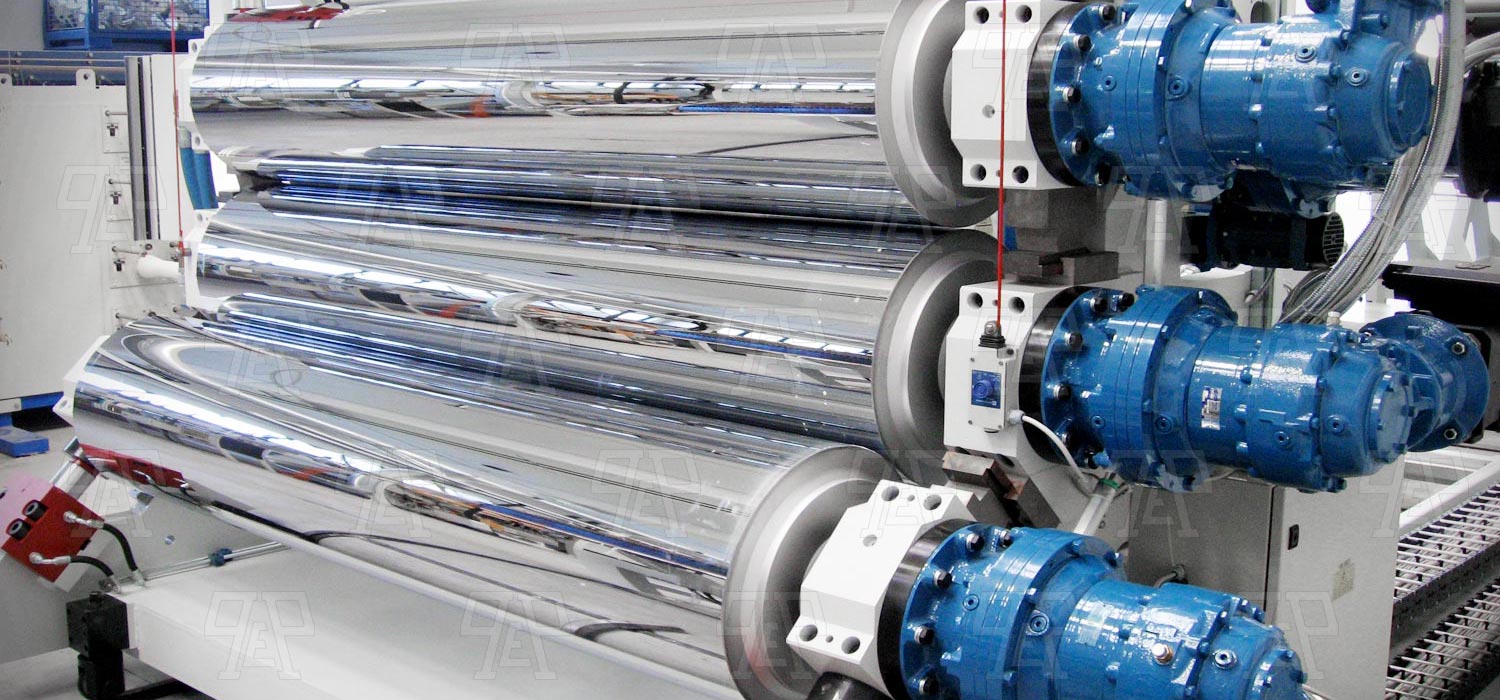

ST52 steel cylinders with a thick double-coated Stellite insert with a 4-layer internal cavity to allow temperature control fluid to flow through it and obtain a constant temperature along the entire surface of the cylinder within 1°C

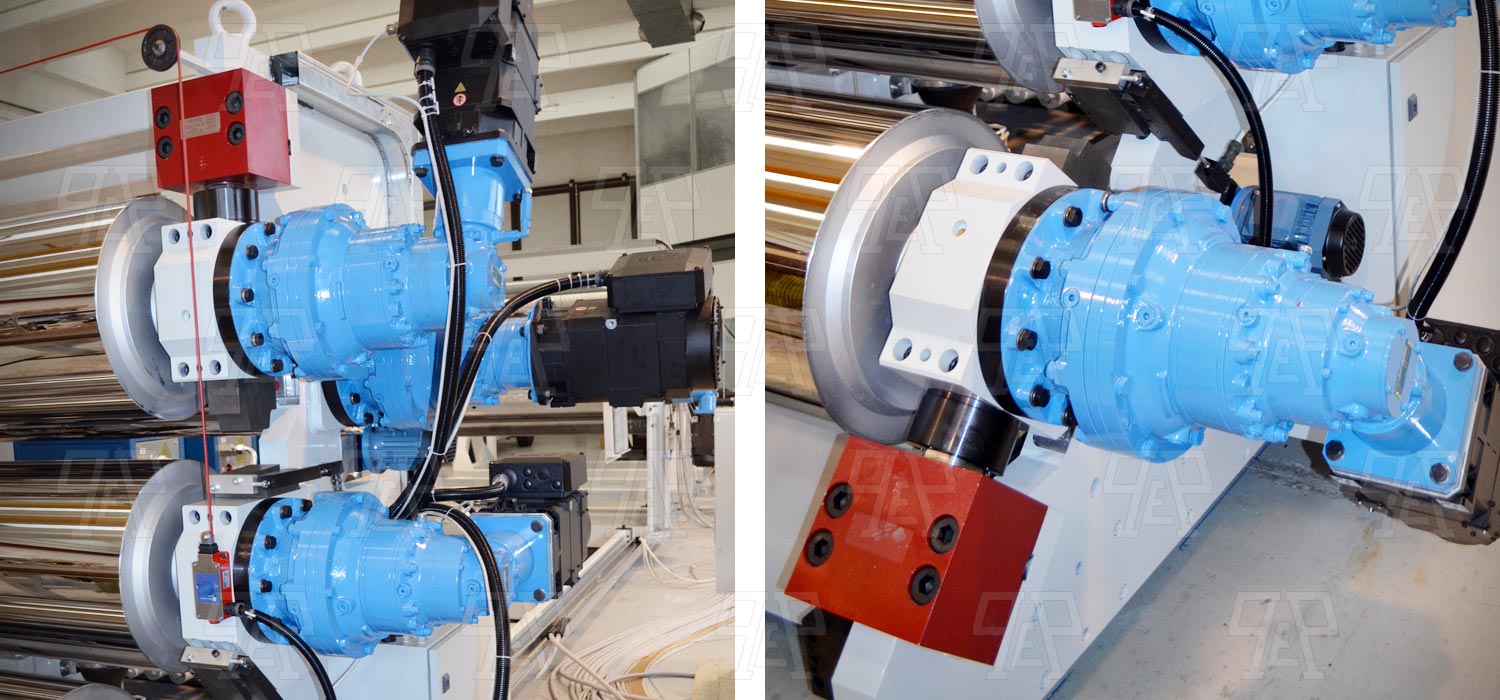

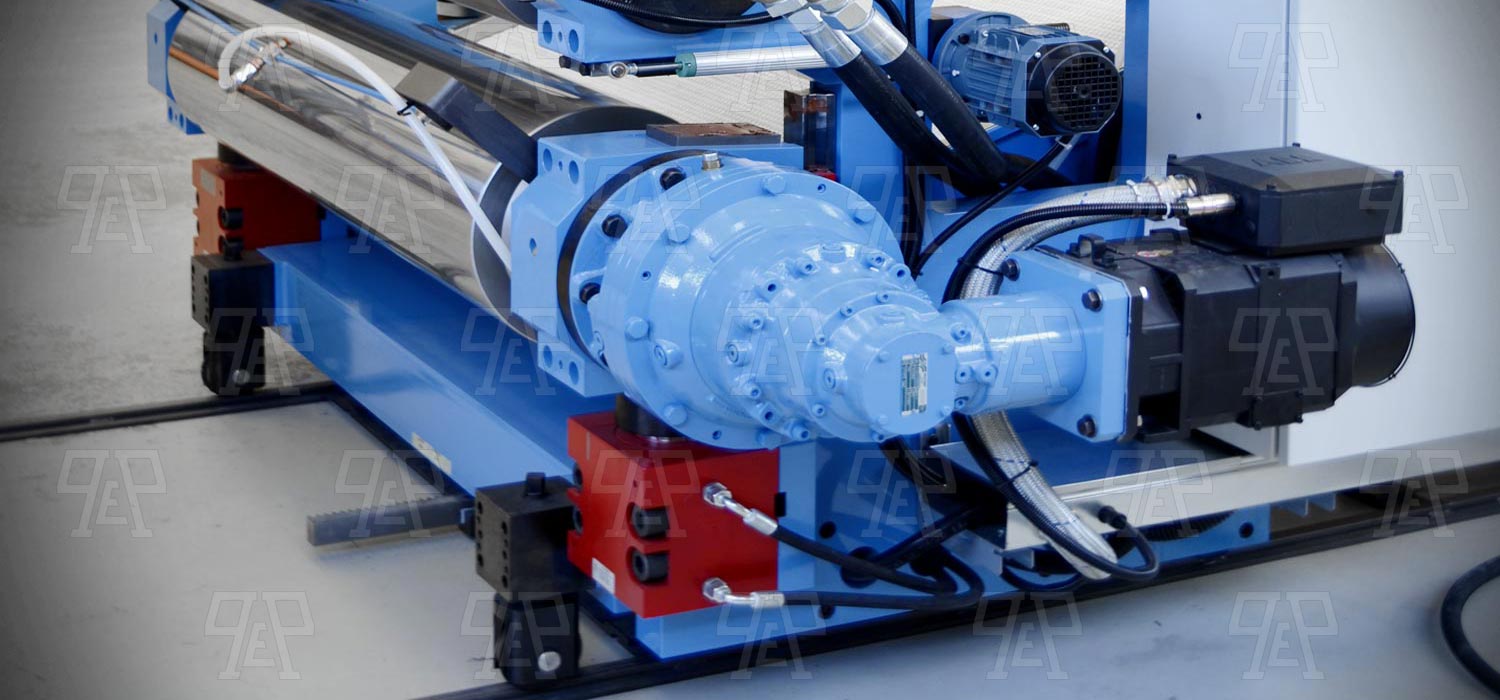

Independent high-density asynchronous motor for each cylinder coupled with gear reducer

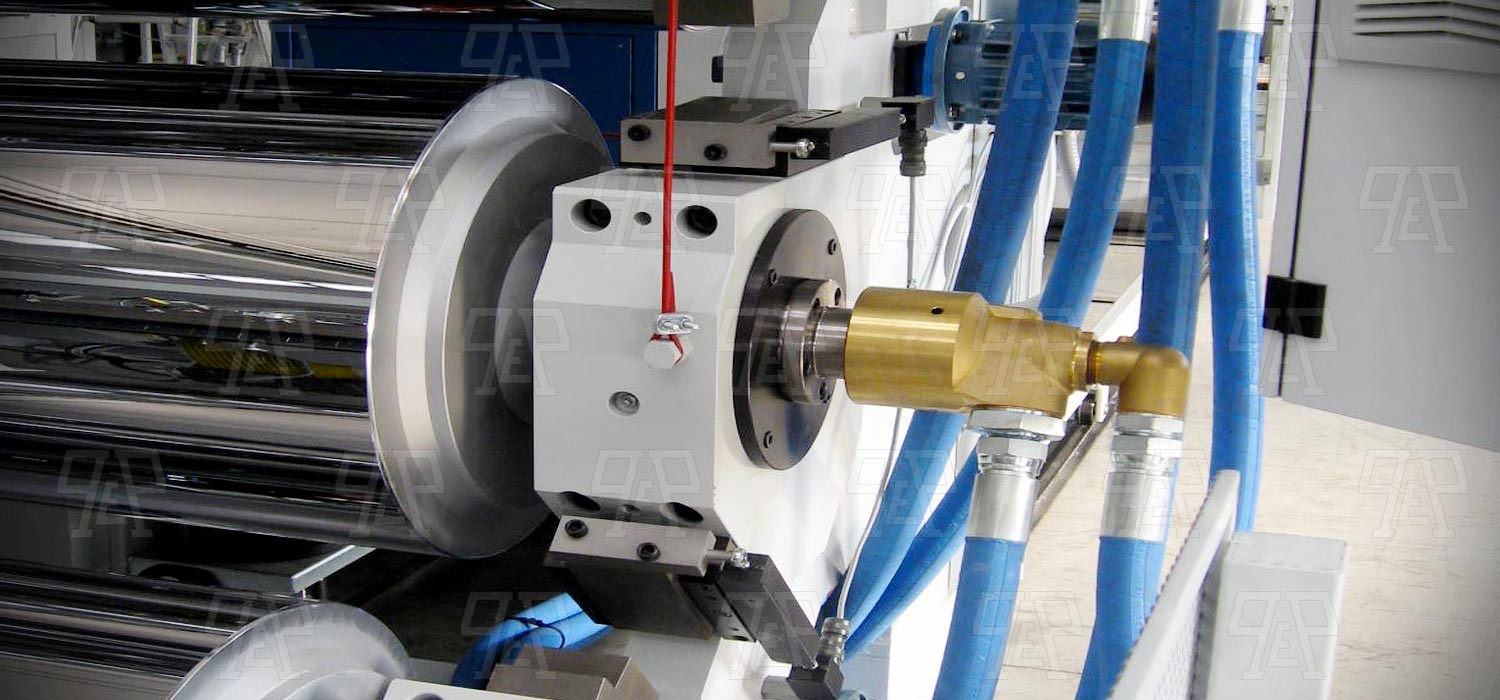

Rotating joint located on one side of the cylinder to allow the temperature control fluid to flow in and out

System with 4 independent wheels for lengthwise movement, height-adjustable to +/- 30mm, to ensure the calender is level. Gearmotor to move the line lengthwise

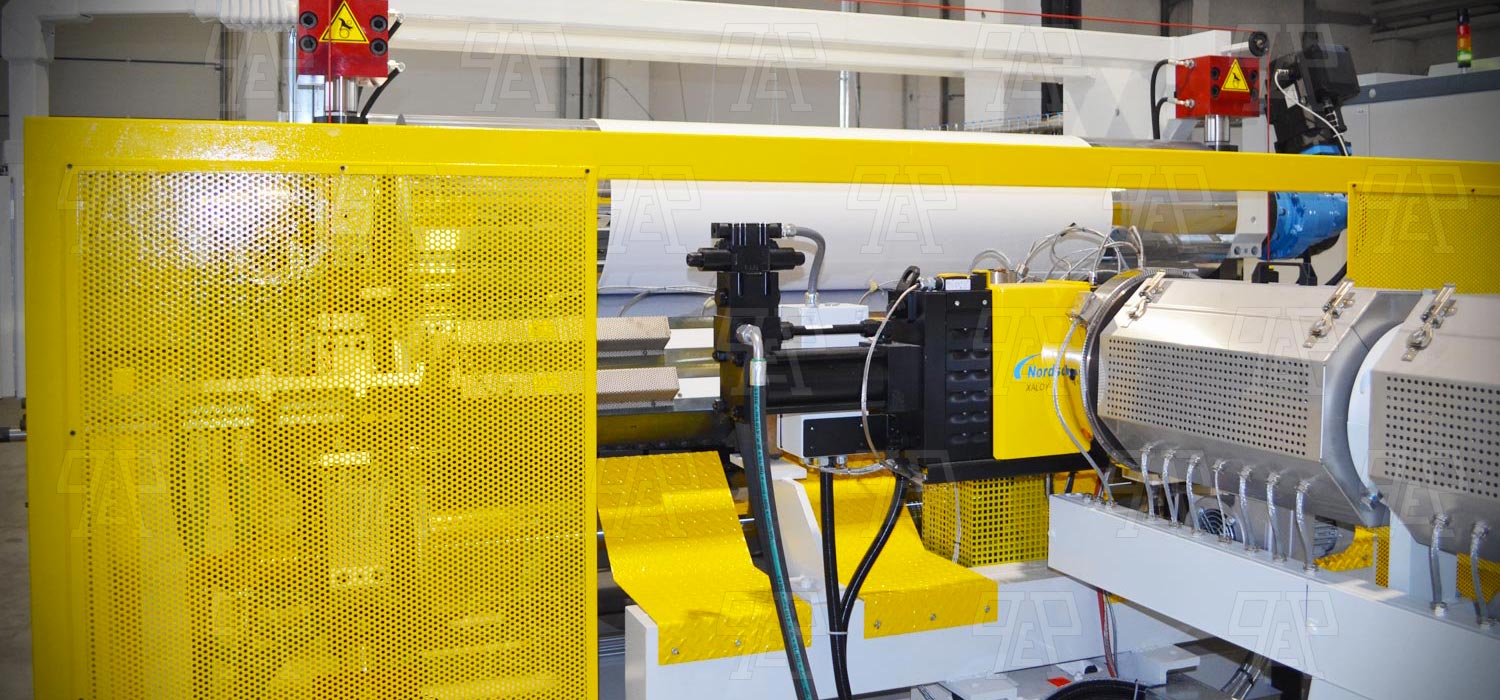

Gates and barriers to prevent access to hazard zones

Safety system with pull cord to rapidly open the cylinders and halt their movement

Technical data

- Number of cylinders: 3-4-5 + additional cooling cylinders

- Cylinder diameter: from 362mm to 700mm

- Cylinder table width: from 1500mm to 3000mm

- Cylinder treatment: Stellite coating

- Cylinder surface appearance: hard chrome plating with mirror finish

- Closure force: 200 kg/lcm

- Closure system: hydraulic

- Thickness adjustment: mechanical wedge system controlled by PLC

- Opening width: 100mm

- Features: independent motor for each cylinder combined with gear reducer

- Peripheral speed: from 0.5 to 15m/min

Proge Plast Engineering

Proge Plast Engineering

Proge Plast Engineering

NEED MORE INFO?

Want to learn more about how Proge Plast Engineering can help your business? Click below to get in touch.